| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

YUHUAN SINCERE TRADING COMPANY LIMITED

NO.28, YINHU ROAD, ECONOMIC DEVELOPMENT ZONE / YUHUAN / ZHEJIANG / CHINA

|

Contact Info: +86 134 5667 6289

|

Hall: 8

Stand: 829A2

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Medical Device Automation Solutions Shunjin Medical Technology - A leading high-tech enterprise based in Yuhuan City, Zhejiang Province with over 20 years of specialized experience in medical device assembly automation. Our Expertise With two decades of industry leadership, our company has established itself as a premier provider of automated manufacturing solutions for the medical device sector. Our comprehensive capabilities include Advanced R&D Team Dedicated specialists continuously exploring innovative automation solutions tailored to medical manufacturing challenges Professional After-Sales Support Expert technicians providing on-site installation, commissioning, and comprehensive personnel training Our Commitment At Shunjin Medical Technology, we operate by three core principles Unique Customization Developing bespoke automation solutions for your specific manufacturing needs Precise Production Delivering equipment that meets the highest standards of accuracy and reliability Lifetime Service Supporting your operations with ongoing maintenance and technical assistance Our Vision We remain committed to advancing medical device automation technology while creating mutually beneficial partnerships with our clients. By continuously enhancing our capabilities and responding to market demands, we aim to drive industry advancement while ensuring your manufacturing success.

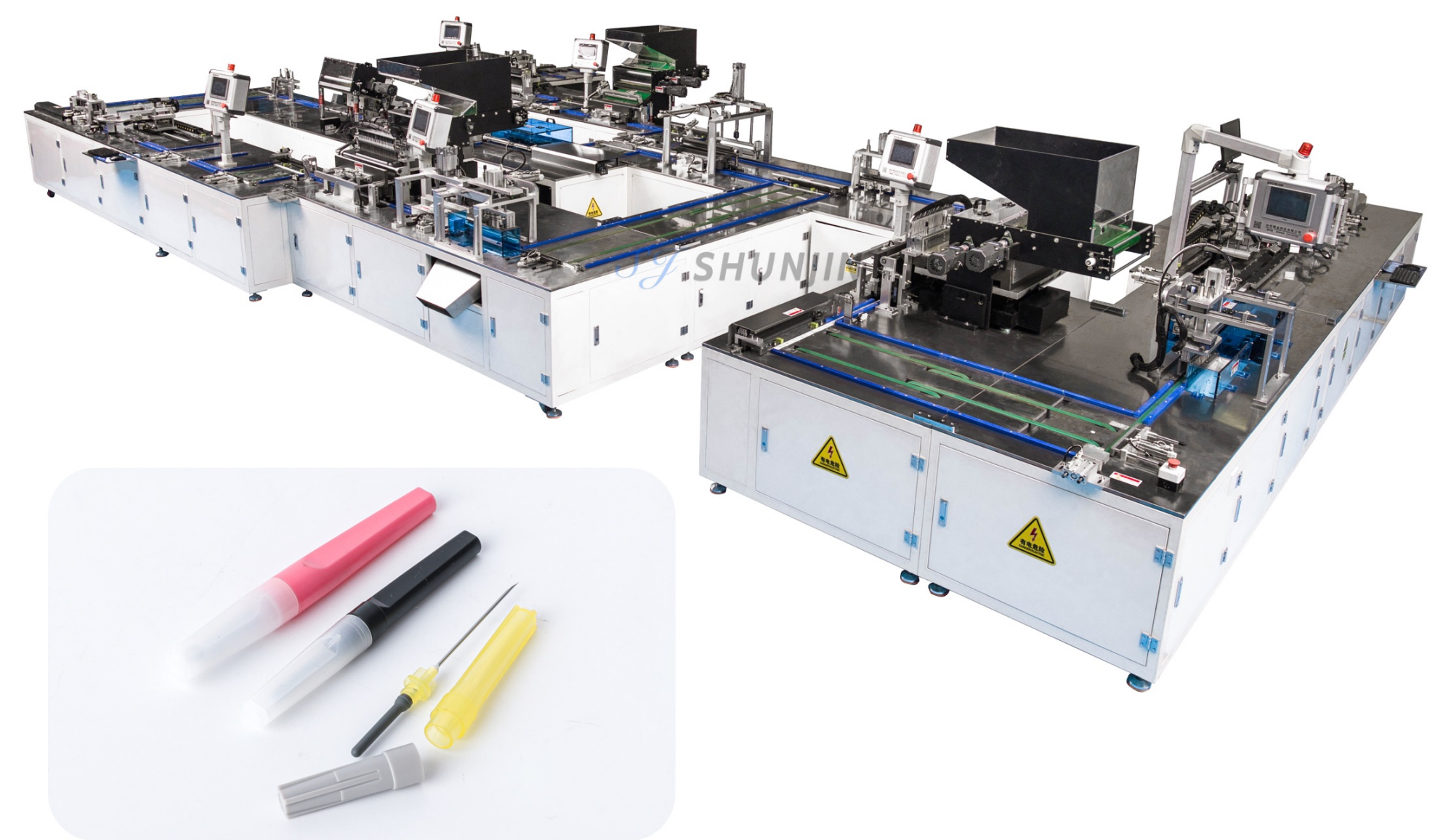

Our advanced automated machine assembles cannulas, hubs, and caps while performing real-time quality inspection. Features built-in imaging detection for burrs and inverted needles with automatic rejection of defective units. Production capacity: 70,000 units per hour. Perfect for medical device manufacturers seeking maximum efficiency without compromising safety.

Our advanced automated machine assembles cannulas, butterfly hubs, and caps while performing real-time quality inspection. Features built-in imaging detection for burrs and inverted needles with automatic rejection of defective units. Production capacity: 8,000-10,000 units per hour. Perfect for medical device manufacturers seeking maximum efficiency without compromising safety.

Our advanced automated machine assembles cannulas, hubs, upper caps, rubber caps, and lower caps while performing real-time quality inspection. Features built-in imaging detection for burrs and inverted needles with automatic rejection of defective units. Production capacity: 12,000-15,000 units per hour. Perfect for medical device manufacturers seeking maximum efficiency without compromising safety.

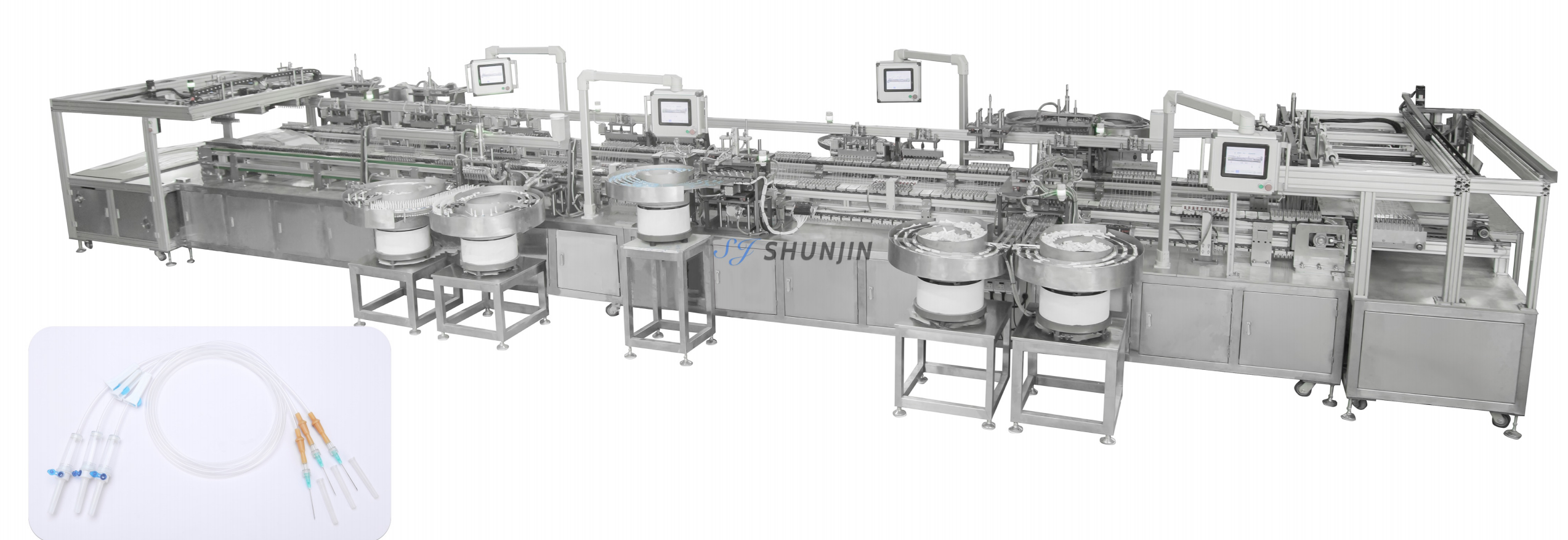

Our advanced system seamlessly assembles all infusion set components: drip chamber, roller clamp, roller, latex tube, luer connector, and needle. Features sensor monitoring at each assembly station plus comprehensive block and leakage testing. Automatically ejects defective products for guaranteed quality. Production capacity: 4,500 units per hour. Streamline your medical device manufacturing with precision and reliability.

Our versatile machine assembles both four-part and six-part drip chambers with precision. Multiple inspection stations verify component quality throughout the process. Unqualified products are automatically ejected to a dedicated collection frame. Production capacity: 5,000 pieces per hour. Enhance your production line with efficient, reliable assembly technology.

Our groundbreaking packing machine handles two infusion set varieties: with Y-port and without. As China s first manufacturer to develop this innovative technology, we offer unprecedented versatility in one system. Production capacity: 3,500 units per hour. Revolutionary packaging solution that delivers flexibility and efficiency.

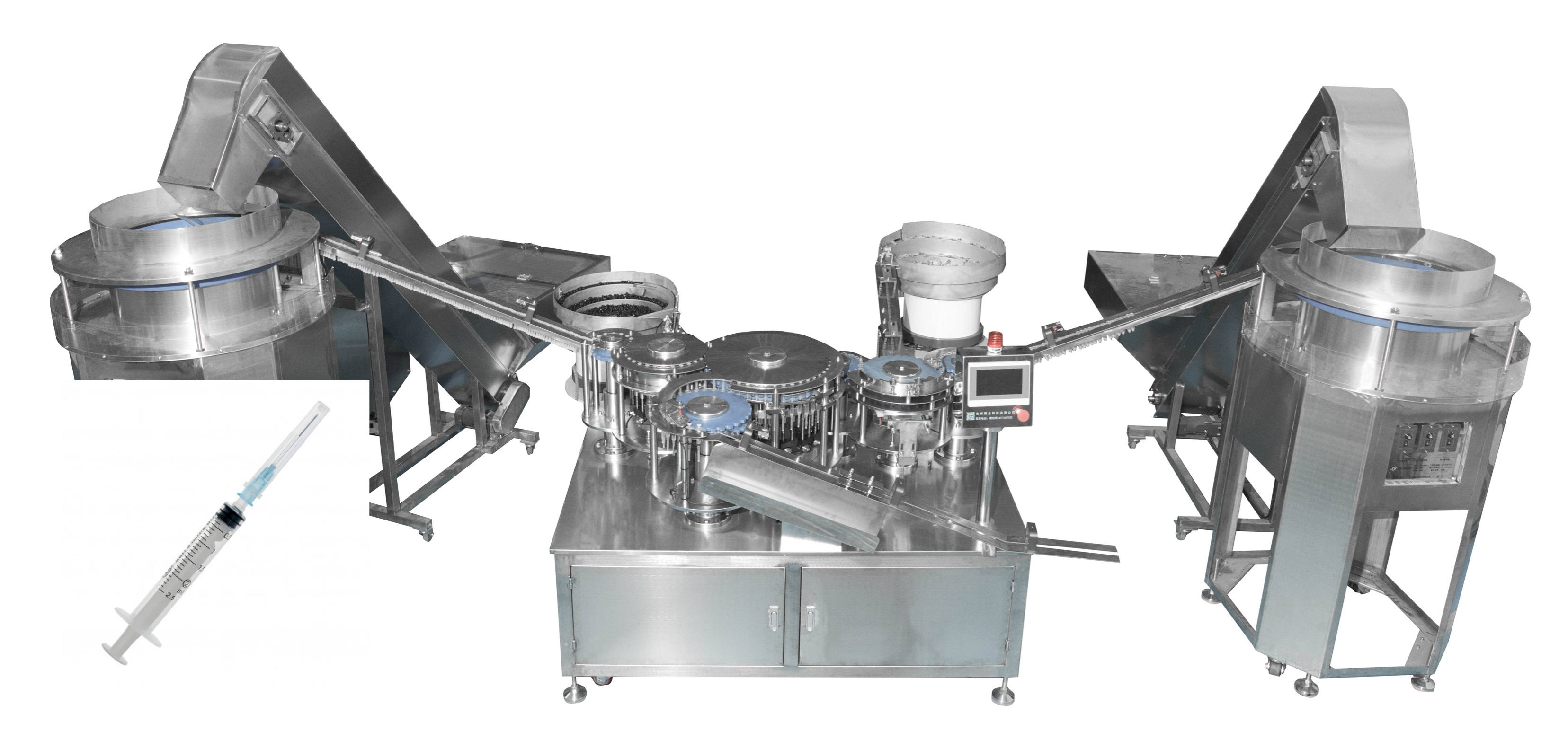

Our advanced rolling pad printing technology delivers exceptionally clear, stable, and precise scale markings on syringes. Featuring high accuracy and impressive output capacity that varies by syringe size: 18,000-22,000 pieces per hour. Superior printing quality meets production efficiency for perfect syringe markings every time.

Our comprehensive assembly system seamlessly integrates syringe barrels, plungers, gaskets, and pre-made needles into complete units. Features integrated quality inspection for plunger and gasket assembly, with automatic sorting of unqualified products to separate collection frames. Production capacity varies by syringe size: 13,000-22,000 pieces per hour. Complete syringe assembly solution combining efficiency with reliable quality control.

Our versatile blister packing system efficiently packages syringes, needles, and various medical devices. Features automatic loading technology that eliminates manual product placement. Interchangeable dies allow for packaging different products including scalp vein sets and infusion sets. Production capacity varies based on product dimensions. Reduce labor costs while increasing packaging efficiency with our adaptable blister packing solution.

No product info found.

No represented companies found.

The company has no registered brand information.

TR

TR